Western Polymers designs and manufactures wear-resistant polyurethane and rubber components that extend equipment life, reduce downtime, and deliver measurable value to industrial operators across Western Canada.

Our products are purpose-built for demanding environments whether keeping airport runways safe with Ice Edge™ snow blades or protecting tubing strings with Tuff-Kote™ rod couplers.

We combine proprietary technology with responsive, local manufacturing to deliver the right solution on time, every time.

Every challenge is different so our approach is built around flexibility and precision.

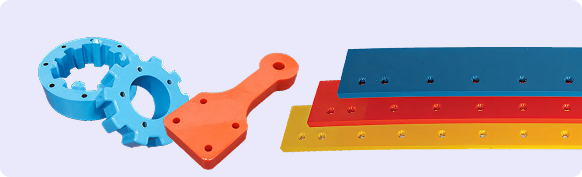

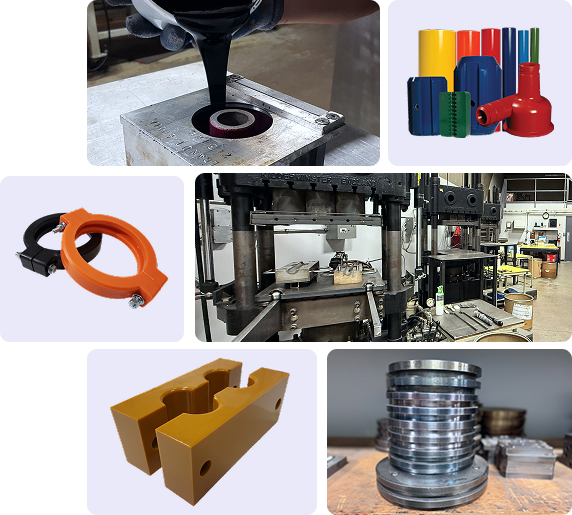

Western Polymers provides complete custom polymer manufacturing solutions, including casting, compression moulding, coating, and machining. Whether you need prototype development, small-batch production, or large-scale runs, we ensure consistent quality and fast turnaround.

Our team collaborates directly with your maintenance, operations, or design group to optimize each part for the environment, load, and lifecycle you require.

Snow Removal Products Purpose-built polyurethane plow blades that outlast rubber and have advantages over steel. Lighter, quieter, and safer for airports, sealed lots, and commercial sites.

Rod Couplers Polyurethane-coated couplers that dramatically reduce rod wear and tubing damage in oilfield operations. Available in multiple configurations for standard and extreme service.

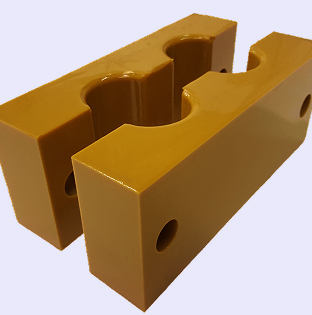

Beyond proprietary product lines, Western Polymers designs and manufactures custom elastomer solutions to address unique wear, sealing, or impact challenges. We work directly with maintenance and engineering teams to rebuild, repair, or redesign components that no longer meet operational needs.

Our capabilities include prototype development and cost-effective small batch production for critical equipment. Whether it’s coating, recasting, or building from scratch, we ensure your custom part performs better, lasts longer, and arrives on schedule.

I needed a cutting edge made for the snow plow I have on my skidsteer.

The manufacturer of my snow blade wanted a crazy amount of money for a replacement, And they wouldn’t be in for 8 weeks! Not cool. I called Matt Wilfort, Plant Manager of Western Polymers and he had one made for me in 10 days!

Highly recommend these folks! 5⭐️

I’ve been using them with my company for years; they offer a service that I can’t find elsewhere. Highly recommended A+ service